When leaking hydrocarbons are encountered at wellheads, at abandoned wells or in well annuli it is critical to understand their origin to design the most efficient workover strategy or well abandonment program. Geochemical fingerprinting technology is a cost effective way to provide unique insights to guide field operations.

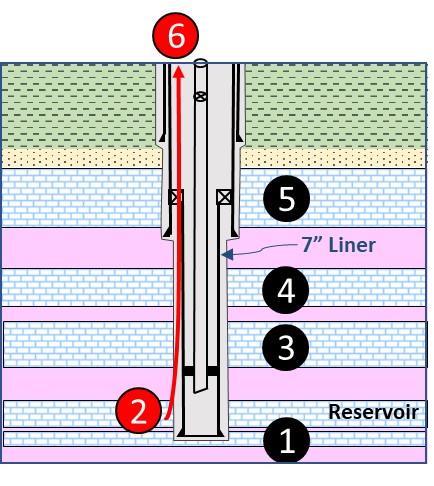

Take the example in Figure 1 (below) which shows a schematic diagram of a development well drilled into a carbonate oil reservoir. The target reservoir zone is encased in salt, with several additional hydrocarbon-bearing zones above and below the target reservoir. After drilling, but prior to production, pressure began to build in the “A” annulus of the well and oil influx was noted. There had been a problem hanging the 7” liner, and this was suspected to be the failure point allowing the hydrocarbons to reach the well head. A decision was required whether to repair the well prior to perforating, or whether a workover could be avoided with the risk that a more costly and risky intervention would be required later to fix the leak. The key was to understand the origin of the leaking fluid and the resulting annular pressure behaviour.

Samples of the leaking oil were taken from the annulus and submitted for geochemical fingerprinting along with cuttings samples from the potential inflow zones. By comparing the geochemical fingerprints of the annulus oil, to the oils extracted from rock samples in the candidate flow zones, the origin of the annulus oil was confirmed to be the primary carbonate reservoir.

Armed with this knowledge, the subsurface team was able to confirm the most likely leak path within the well and to determine that the leak could be managed without resorting to a costly workover. (Under the conditions at the top of the leaking reservoir interval, natural salt creep sealed off the annulus between the liner and wellbore to generate a barrier and restore the integrity of the well*).

Similar logic can be applied to identify potential inflow zones supplying oil or gas into wells at time of abandonment. By integrating geology, geochemical fingerprinting and well engineering information, we can identify leak paths. This knowledge makes remedial workover operations more efficient by targeting specific zones of failure. For example, one operator found repeated gas influx into abandoned wells from an overburden zone that had been assumed not to be hydrocarbon bearing. Geochemical data showed that this apparently minor zone did, in fact, contain gas that matched the annulus gases. Supporting geological evaluation demonstrated the lateral extent of the sand and provided information to allow the operator to incorporate isolation of this zone into their future well abandonment design.

If you would like to discuss how geochemical fingerprinting might contribute to your asset management or your abandonment program, please e-mail info@merlinenergy.co.uk

*Soek, Harry, Mark Laws, Paul Taylor, and Janos Urai (2004) Geochemistry and natural salt closure combine to prevent a costly workover: case study from a deep overpressured well in South Oman. GEO 2004 Conference presentations (March 7-10, 2004, Bahrain).